New Product Technology

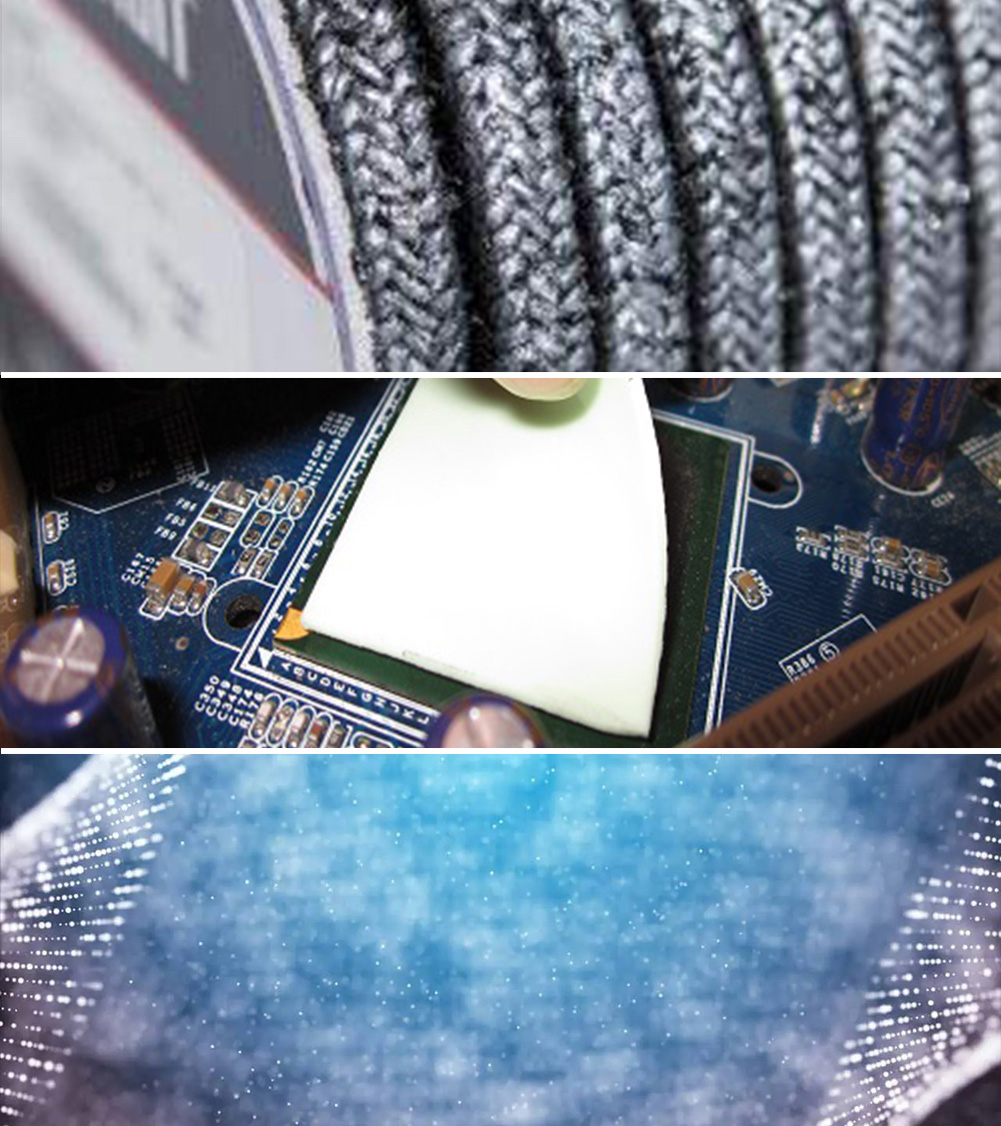

Carbon fiber gasket

Carbon-based substrate, very high thermal conductivity, the actual test value is 20W/mk~35W/mk, can be used in high-power base station servers with large heat output

Phase change material

Different from the general thermal grease, the sheet is easy to use, achieve low thermal resistance, and solve the problems like silicone grease easy to dry, oil separation, scraping causing operation…

Non-silicone oil heat conductive sheet

The main component is acrylic PMMA(acrylic resin), high weather resistance and stability, no silicone oil component, no siloxane molecule volatilization problem

New Installations

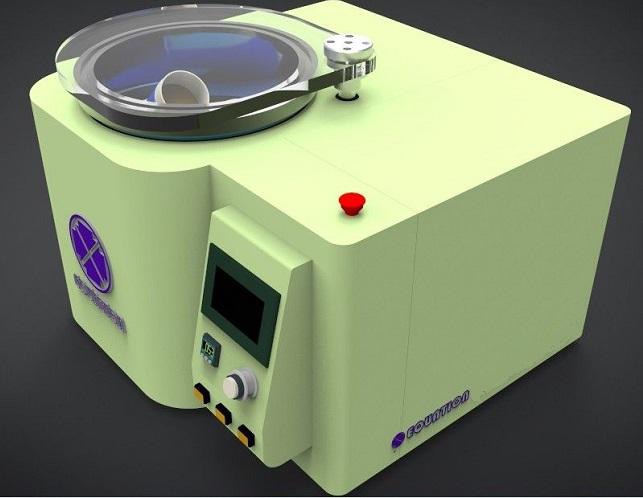

Centrifugal Degassing Chamber

The Degasser Chamber removes the entrained gas from our Thermal Silicone Materials by letting the material entity being placed into the Degasser and spread into a thin layer and subjected to centrifugal force. This increases the buoyant force on the tiny gas bubbles as they migrate to the center of rotation. When they reach the surface of the mud, they pop and become free gas

分划线

Thermal Shock Test Chamber

This Chamber is a machine being used to test the effects of specified environmental conditions on our Thermal Silicone Materials and/or related electronic materials.

This chamber conducts test involving testing of products to different conditions by simulating exposure to stipulated climate or excessive ambient conditions for a product or a material under laboratory-controlled conditions. The main purpose is to see how materials will react during exposure to changes in extreme climatic conditions, such as going from extremely cold to extremely hot conditions (Thermal Shock) in a very short time